In the mining and building materials industries, dewatering screens play a vital role as an efficient and reliable dewatering equipment. It can not only effectively remove excess moisture from materials, but also improve the overall quality of materials, creating favorable conditions for subsequent processing and utilization.

1. Working principle of dewatering screens

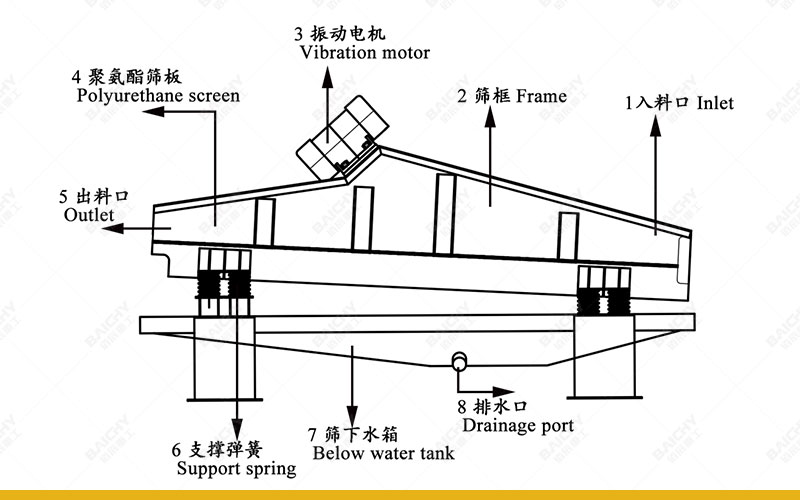

The dewatering screen effectively separates moisture from solid particles in wet materials through its unique screening and vibration mechanism. During the screening process, the material is evenly distributed on the screen. As the screen vibrates, fine moisture and particles are discharged through the pores of the screen, while larger solid particles remain on the screen, thereby achieving the purpose of dehydration.

2. Application of dewatering screens in mining

In the mining field, dewatering screens are widely used in ore washing, dehydration, desludging, and other process links. It can effectively remove mud and moisture on the surface of ore, improve the grade and purity of ore, and provide high-quality raw materials for subsequent smelting and processing. At the same time, the dewatering screen can also reduce the weight and cost during transportation and improve the overall economic benefits.

3. Application of dewatering screen in building materials industry

In the building materials industry, the dewatering screen also plays an important role. It is widely used in the dewatering of materials such as sand and gravel, ceramic raw materials, cement clinker, etc. Through the treatment of dewatering screens, these materials can remove excess water, improve the density and strength of the materials, and thus meet the production requirements of building materials products. In addition, dewatering screens can also reduce the viscosity and fluidity of materials, and reduce energy consumption and costs in the production process.

4. Advantages and characteristics of dewatering screen

• Efficient dewatering: The dewatering screen adopts advanced screening and vibration technology to achieve a fast and efficient dewatering effect.

• Stable and reliable: The equipment has a sturdy structure, stable vibration, stable and reliable operation, and low failure rate.

• Wide range of applications: It is suitable for the dewatering of a variety of materials, such as ore, sand and gravel, ceramic raw materials, etc.

• Easy to maintain: The equipment has a simple structure and convenient maintenance, which reduces maintenance costs and downtime.

As key dewatering equipment in the mining and building materials industries, the dewatering screen plays an important role in improving material quality, reducing production costs, and improving economic benefits. With the continuous advancement of technology and the continuous development of the industry, the application prospects of dewatering screens will be broader.